Products

HYDRAULIK

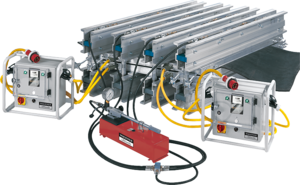

Our hydraulic Vulcanizing

• robust and firm construction • long life

Features

- high level of safety by passing traction bolts through the cross beam profile

- conventional, robust heating plates combined with hydraulic pressure systems allow splicing even on partially worn belts

- heating plate with air or water cooling

- exact temperature regulation via an electronic control box

- easier and faster pressure buildup by changing piston hand

pump or motor pump unit

Heating plates

• heating plates of frame-type construction, made of a high- quality corrosion-resistant aluminium alloy

- shape: rhombic 16° 42’; 22°, rectangular 90°

- optionally available with air and/or water cooling

- robust, flush fitting electrical connections guarantee safe

operation

- optimum pressure and temperature distribution

- minimum temperature tolerance over the entire heating plate

Splicing by using a single heating plate (Edge zone heating) edge heating, type KH

- in order to compensate heat losses in the edge areas (edges)

of the heating plates, they are provided with a greater hea-

ting capacity in the edge area than in the core area

- the heating capacity is calculated in such a way that a uniform,

constant temperature can be guaranteed over the entire hea- ting area

Edge switch, type KS

- edge zone heating can be switched on and off.

- the combination of two or more heating plates is prevented

by the star knob at the edge of the heating plate

- the edge zone heating is turned off by unscrewing the star

knob beforehand

- if the heating plate is to be used on its own, the star knob

should be screwed in again and edge zone heating is swit- ched on again (the heating plate can be used on its own and as a combined plate in a group)

Modular assembly of multiple small heating plates to make a splice

- in order to compensate heat losses in the edge areas (edges)

- using several smaller heating plates instead of just one simpli-

fies the handling of a vulcanizing press

- an assembly of several conventional heating plates in com-

bination can cause hot spots at the edges of two plates and damage the conveyor belt. Damage of this type is avoided by using heating plates with combination edges or edge switches

Combi-edge, type KK

• the use of heating plates in combination was taken into consideration at the design stage

• the heating capacities of adjacent edges are designed to be lower (in this case usually the heating plates are not used alone)

Download information

Send inquiry